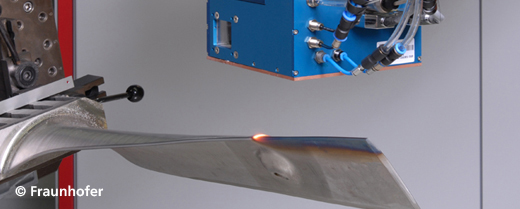

Overview

Laser hardening can be used to locally improve the wear resistance and service life of parts for a wide variety of applications from press forming tools to oil drilling equipment. The technology is especially suitable for selective hardening of complex shaped parts, bores or edges, and applications where minimal heat input into the surrounding material is critical. Laser hardening is typically applied for transformation hardening of ferrous materials such as hardenable steels and cast irons.

Process Advantages

- Precise and localized heat input

- Outstanding wear properties

- Self-quenching process

- Low loss of part ductility

- No need for post-process machining

- Minimal heat input and hence low thermal distortion

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW