Overview

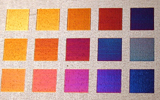

Lasers can be used to create permanent color marking on a metal surface. Laser color marking is based on surface oxidation and thin film effects and does not use any chemicals, coatings or tools. Different colors ranging from silver and gold to blue and green can be created. To create uniform and high quality marks, the laser must have a good beam quality, stability and should allow independent pulse parameter adjustment. Only changes in laser process parameters are required for changing colors. Color marking with lasers makes the surface visually more attractive and is gaining interest for consumer products.

Process Advantages

- No coatings or chemicals

- No tools or dies

- High contrast, high accuracy and high quality coloring

- Flexible marking process using digital image

- Different colors by changing the laser parameters

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW