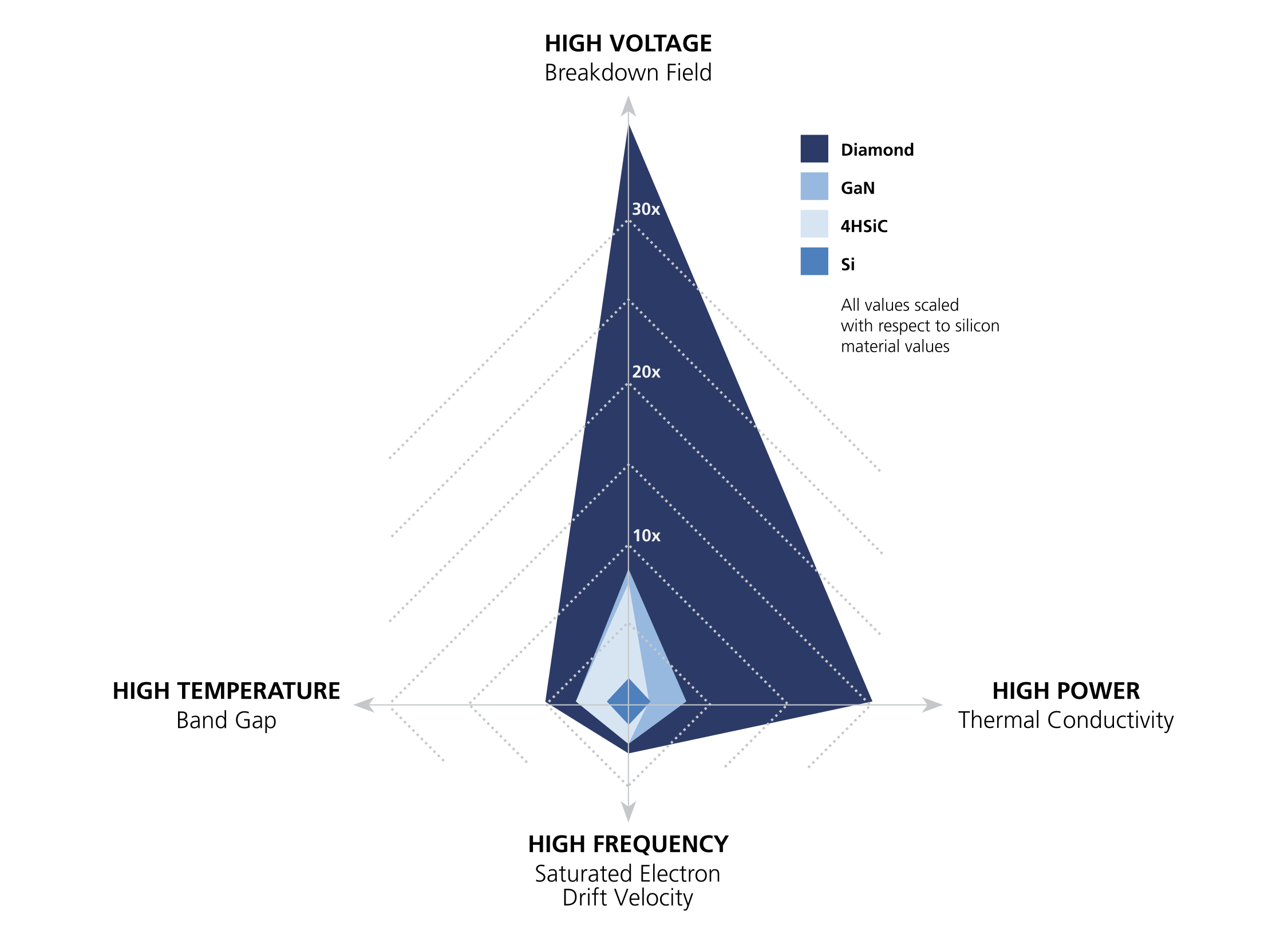

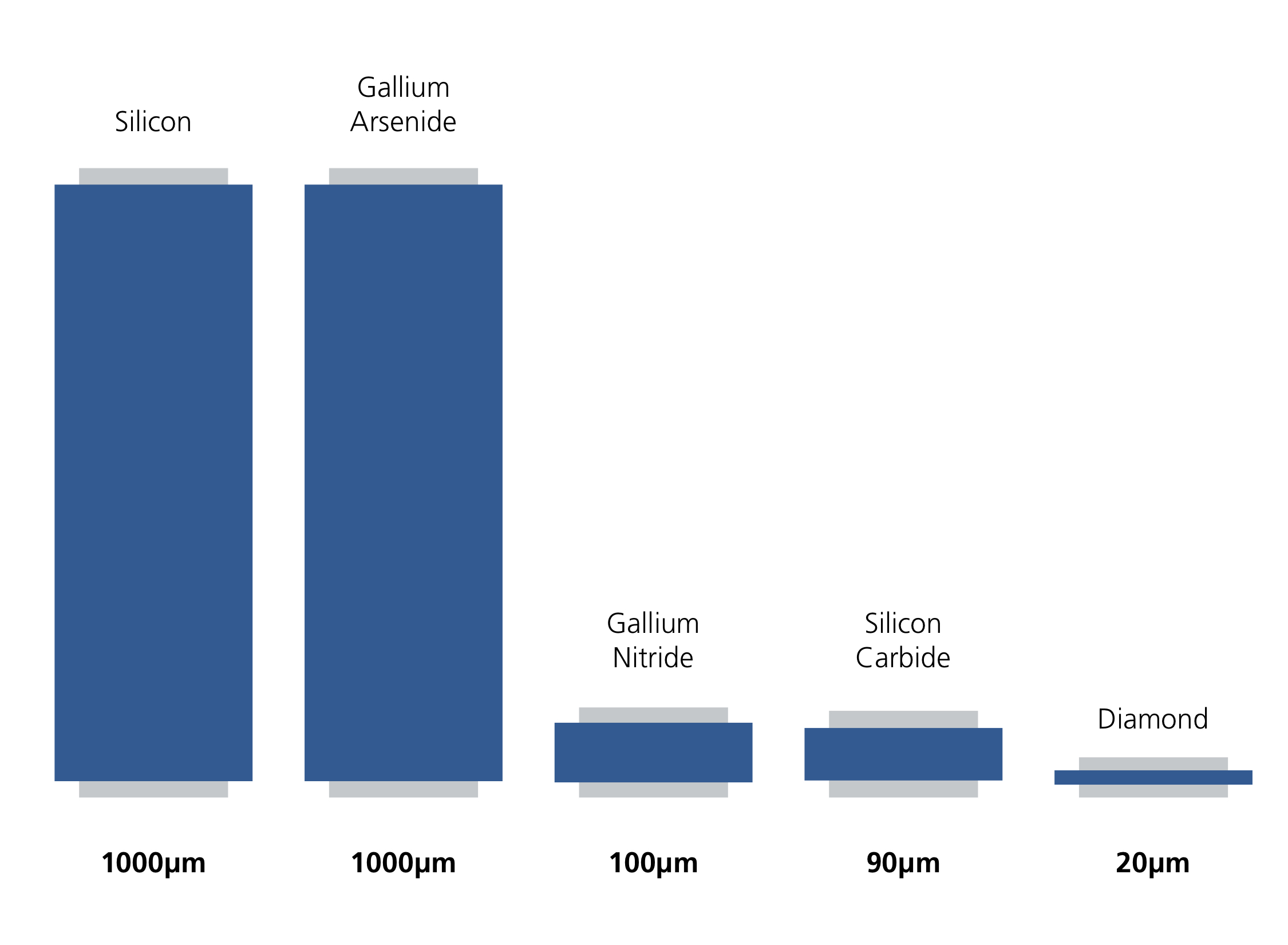

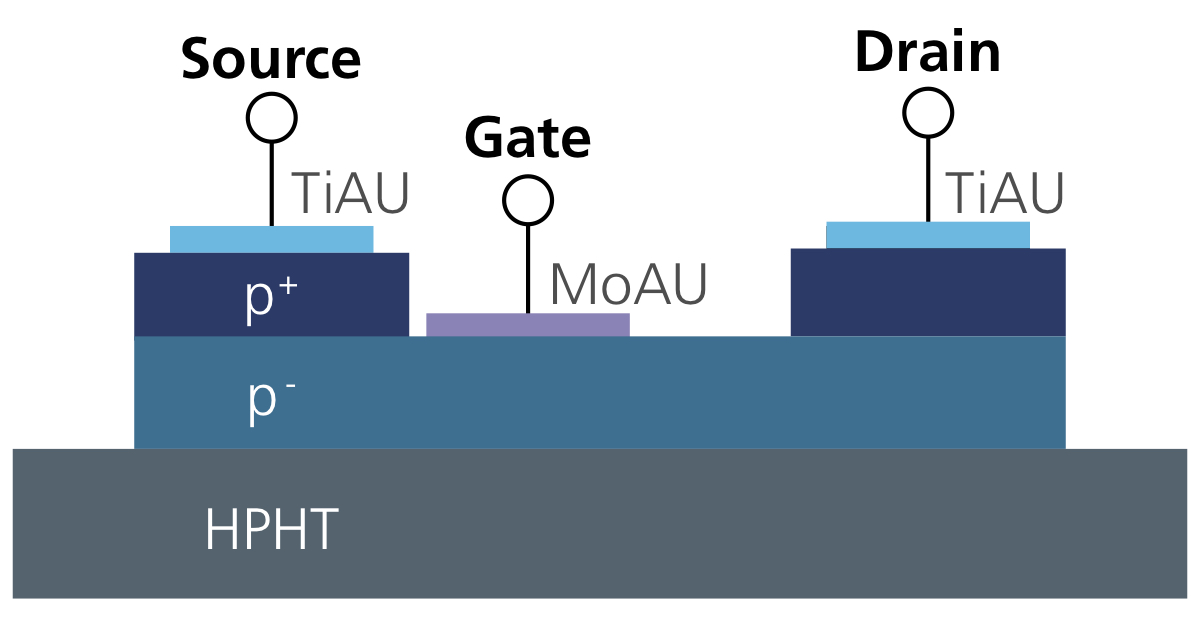

Diamond, among others, has properties which make it particularly useful as electronic material. As displayed by the figure of merit (Figure 1) it can be seen that key properties, such as the bandgap, the saturated electron drift velocity and the electric breakdown field outshine silicon by leagues, but also outperform current choices for high-power and high-frequency electronics, namely silicon carbide and gallium nitride (Figure 2). This makes diamond electronics particularly interesting for high-power and high-frequency applications.

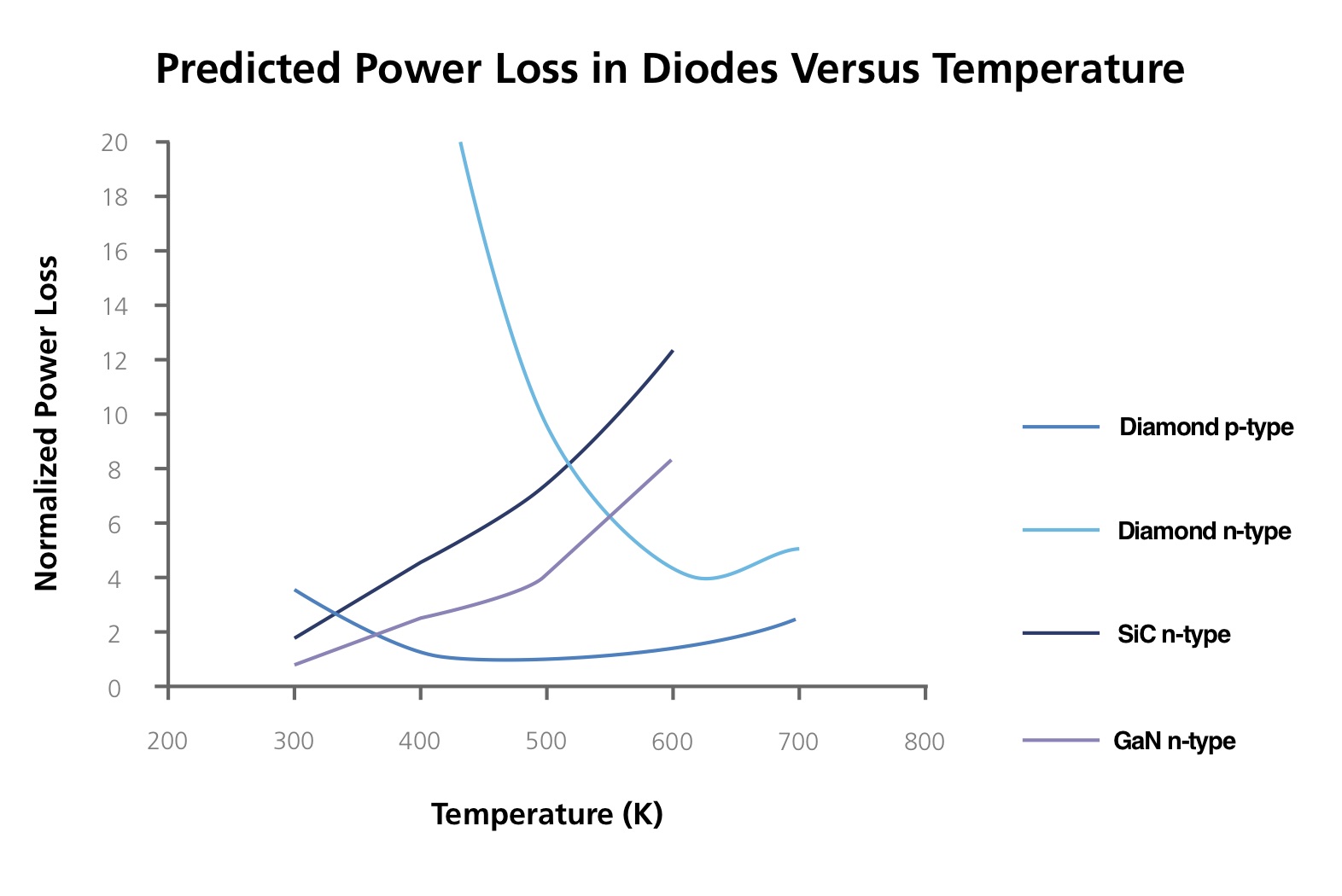

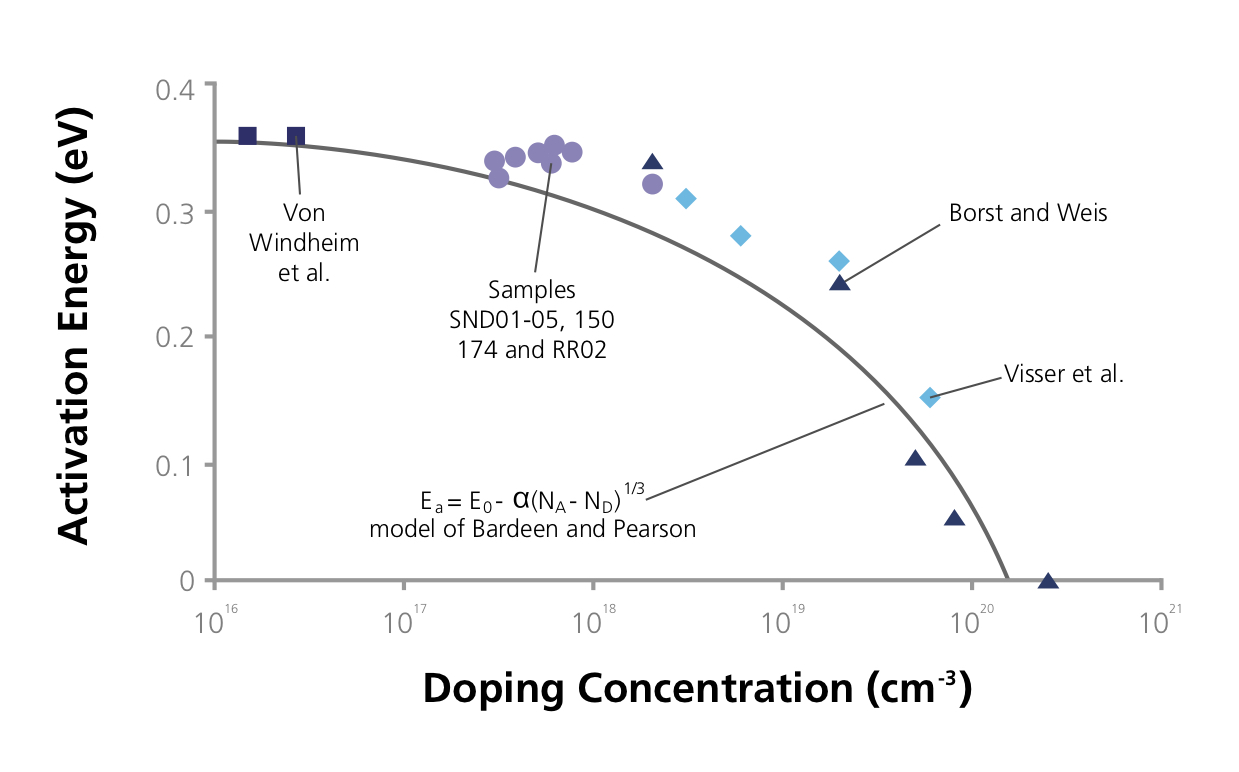

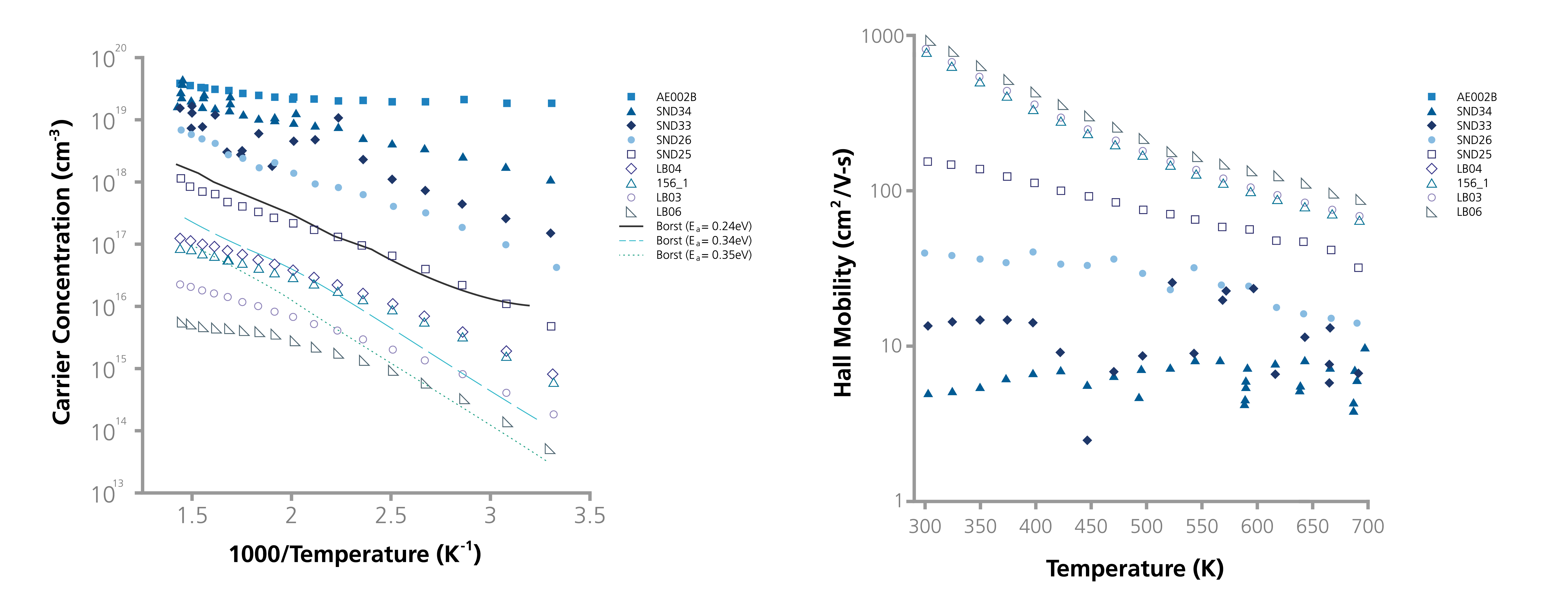

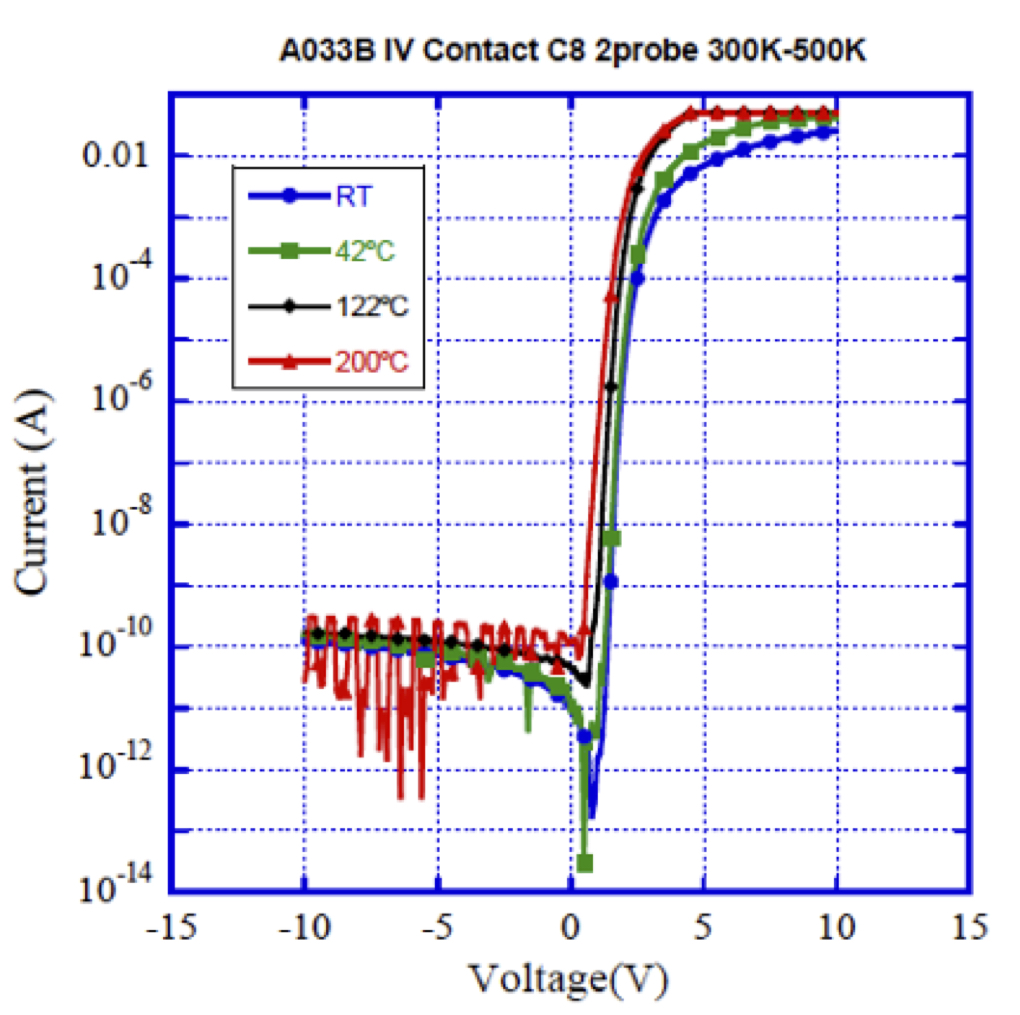

Conduction in diamond can be achieved by doping using boron for p-type conduction and phosphorus for n-type conduction. Both, p-type (0.37 eV) and n-type (0.55 eV) dopants are rather deep donors. This means that diamond electronics is actually performing best at elevated temperatures. This is in stark contrast to competing semiconductor materials such as SiC and GaN (Figure 3). With diamond’s performance being optimal above 300°C

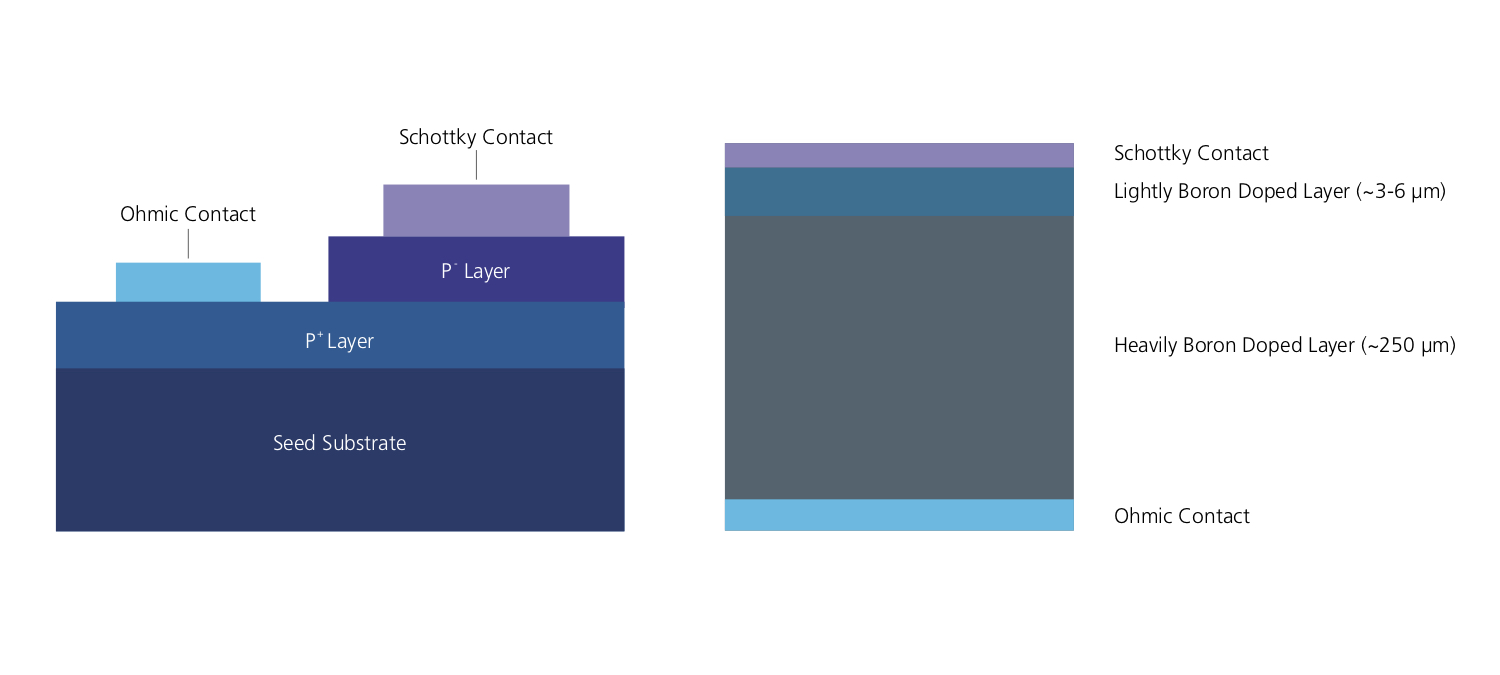

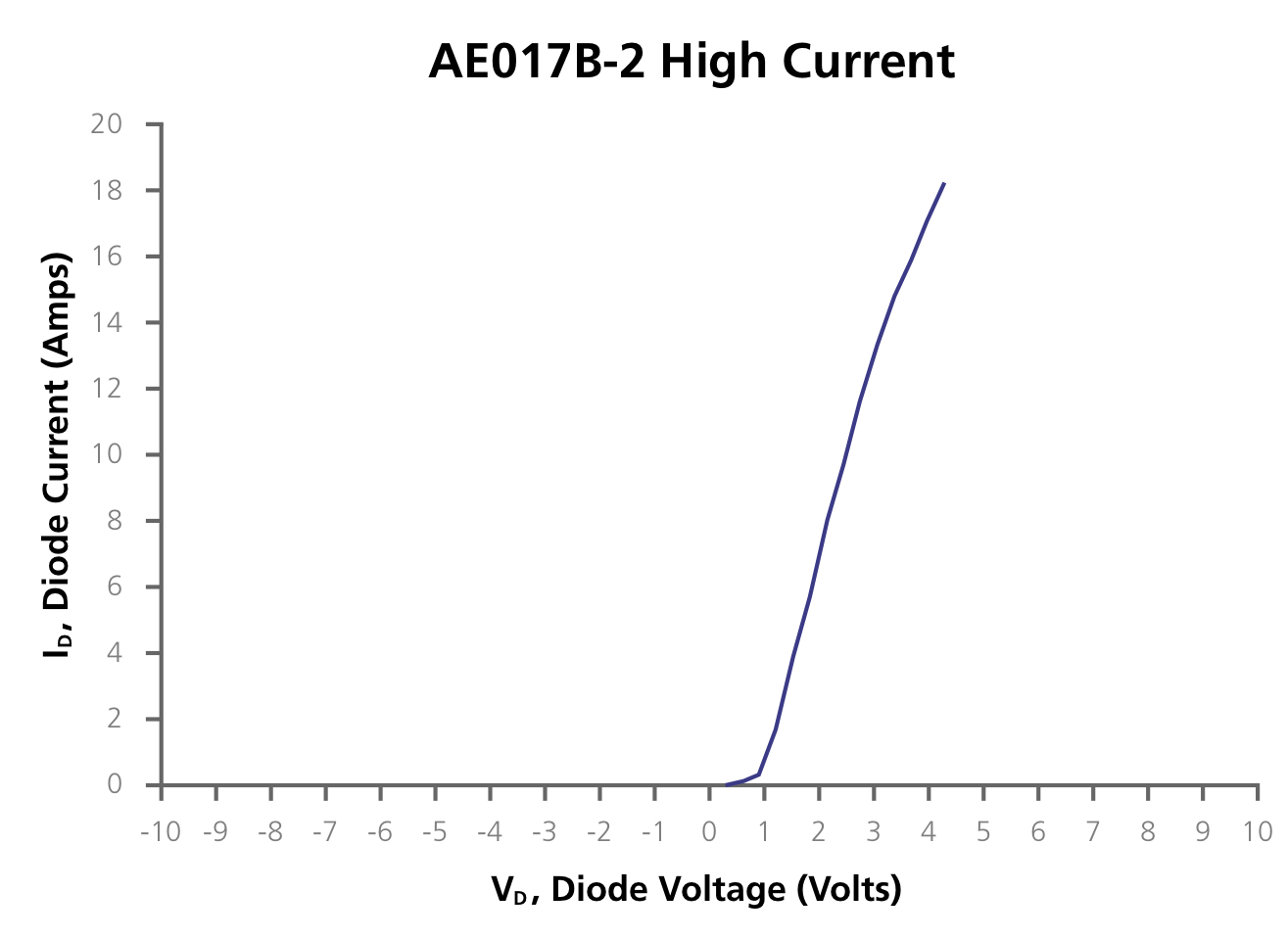

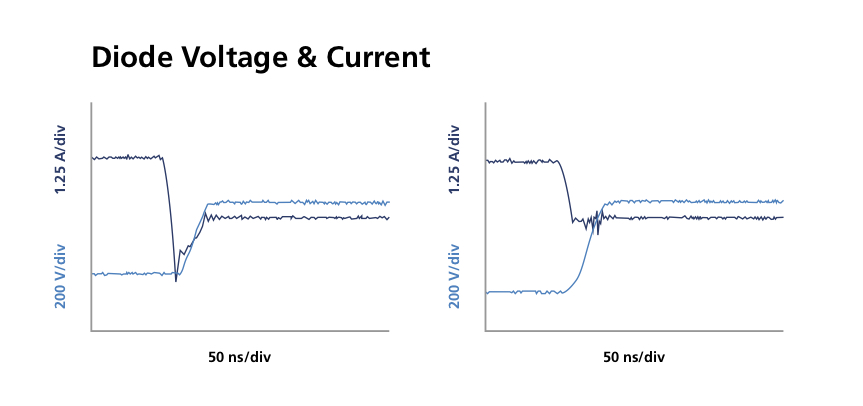

Diamond-based power electronics will operate safely at high temperatures without the extensive cooling and circuit protection required in today’s high-power systems. The exceptional semiconductor properties of diamond will enable a new class of high-power, high-voltage electronic devices and will transform applications in transportation, manufacturing, communication and energy sectors.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW