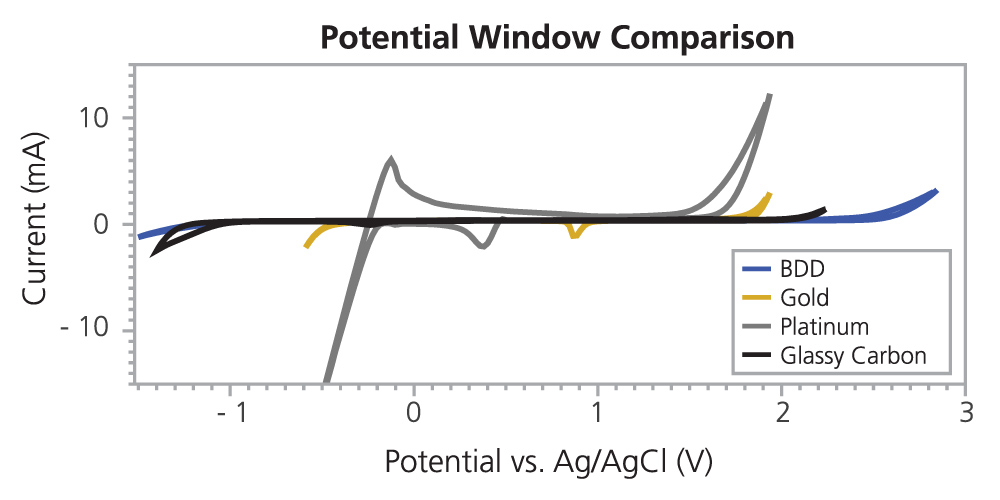

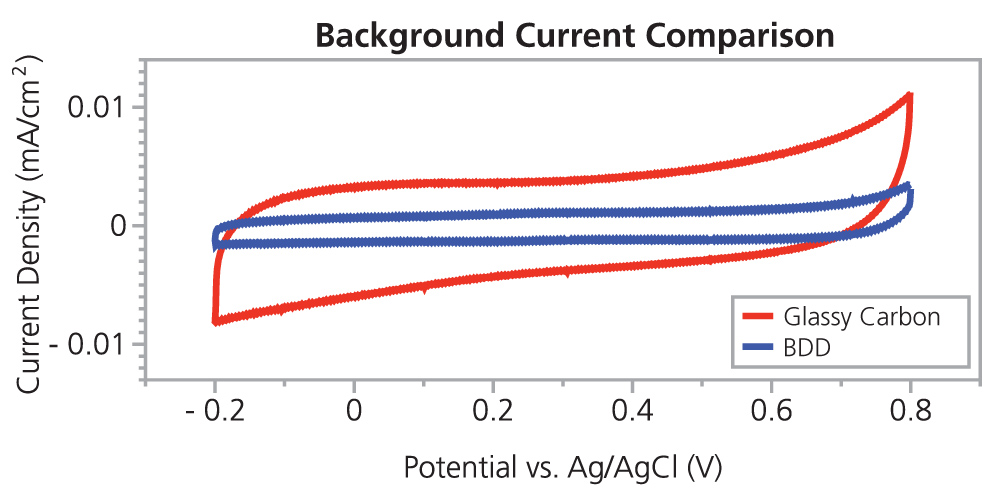

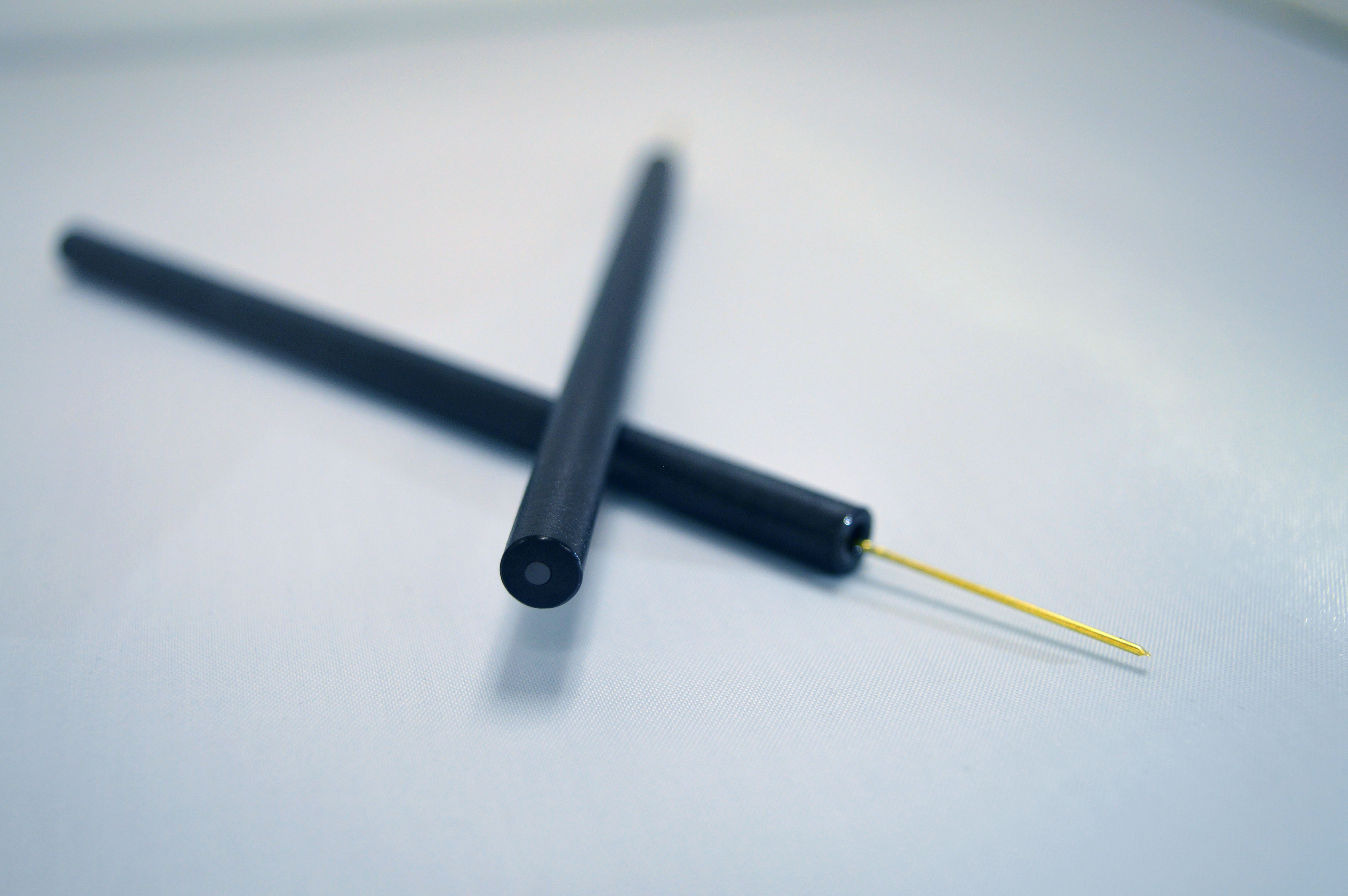

Boron-doped diamond (BDD) is an excellent electrode material with a large potential window in aqueous solution and low background current. The wider potential window and lower background currents make the BDD material very attractive for electrochemical analysis experiments. Reactions occurring in potential ranges from about -0.5V to -1.2V and about +1.8V to 2.5V can now be analyzed which could not be analyzed on traditional electrode surfaces such as Au and Pt. The lower background current allows for higher sensitivity and lower detection limits. Extreme stability, biocompatibility and resistance to surface fouling are added benefits to this exceptional electrode material.

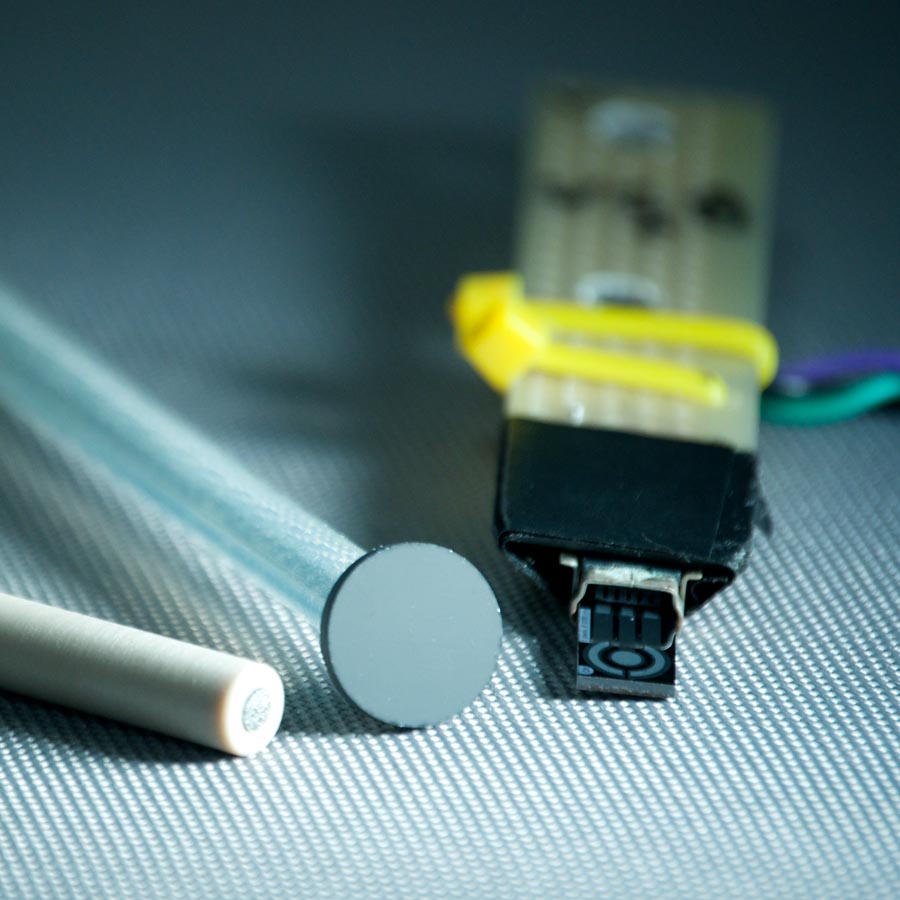

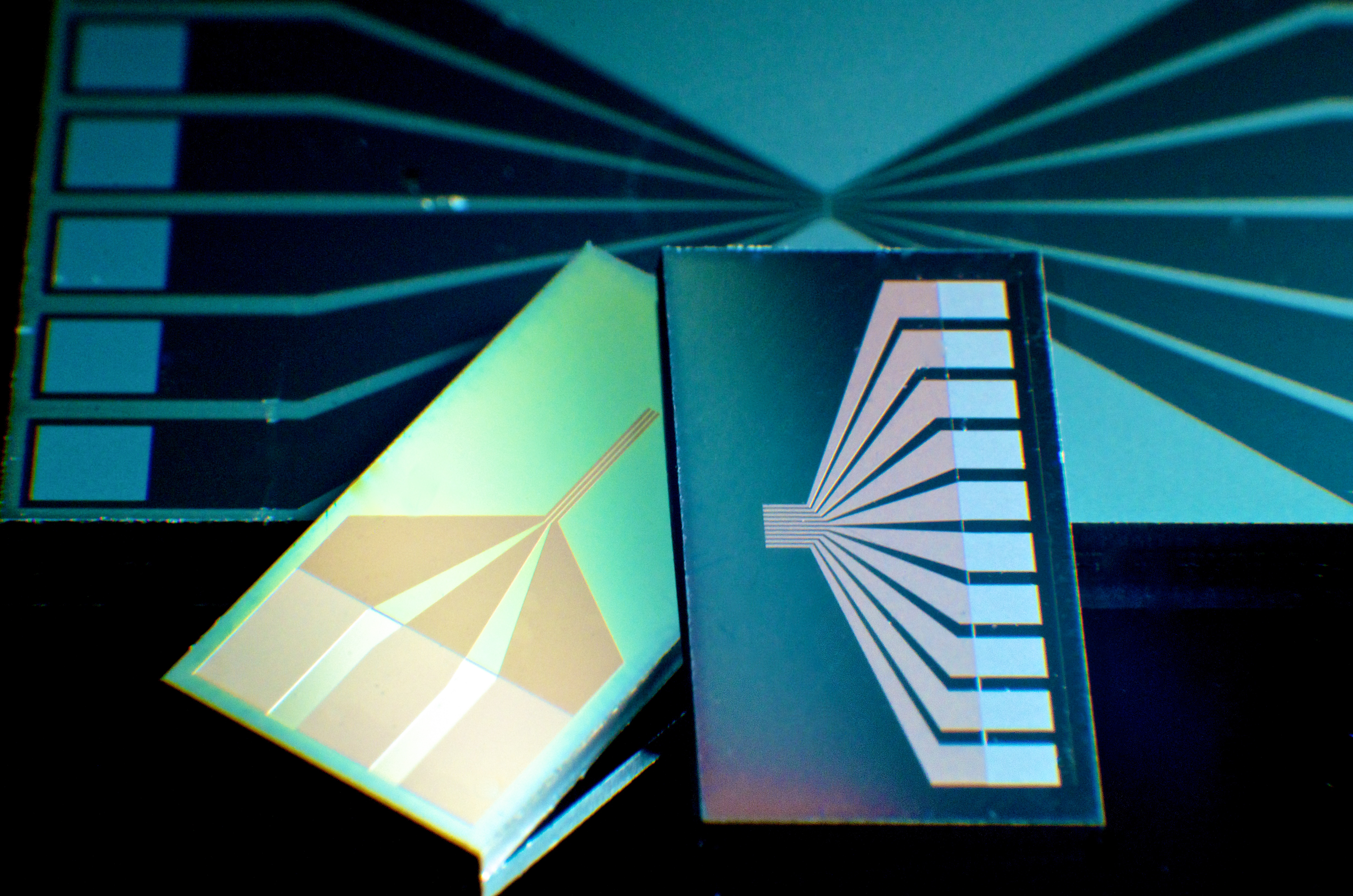

The Fraunhofer USA Center Midwest has developed a large portfolio of boron-doped diamond electrodes and materials targeting a broad range of markets including biotechnology, environment and health. The available portfolio is offered to collaborators and project partners to further advance the technology and develop products. The portfolio includes:

• Thin film electrodes on silicon, quartz and metal substrates

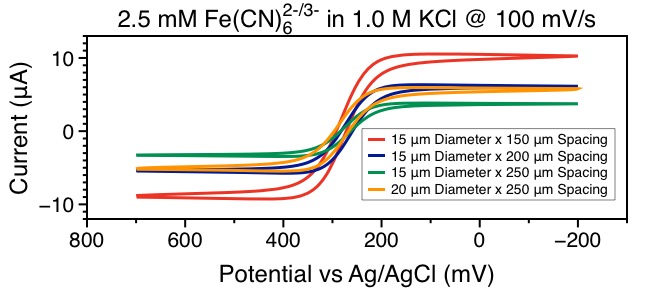

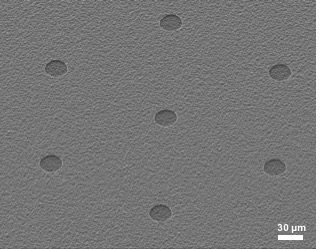

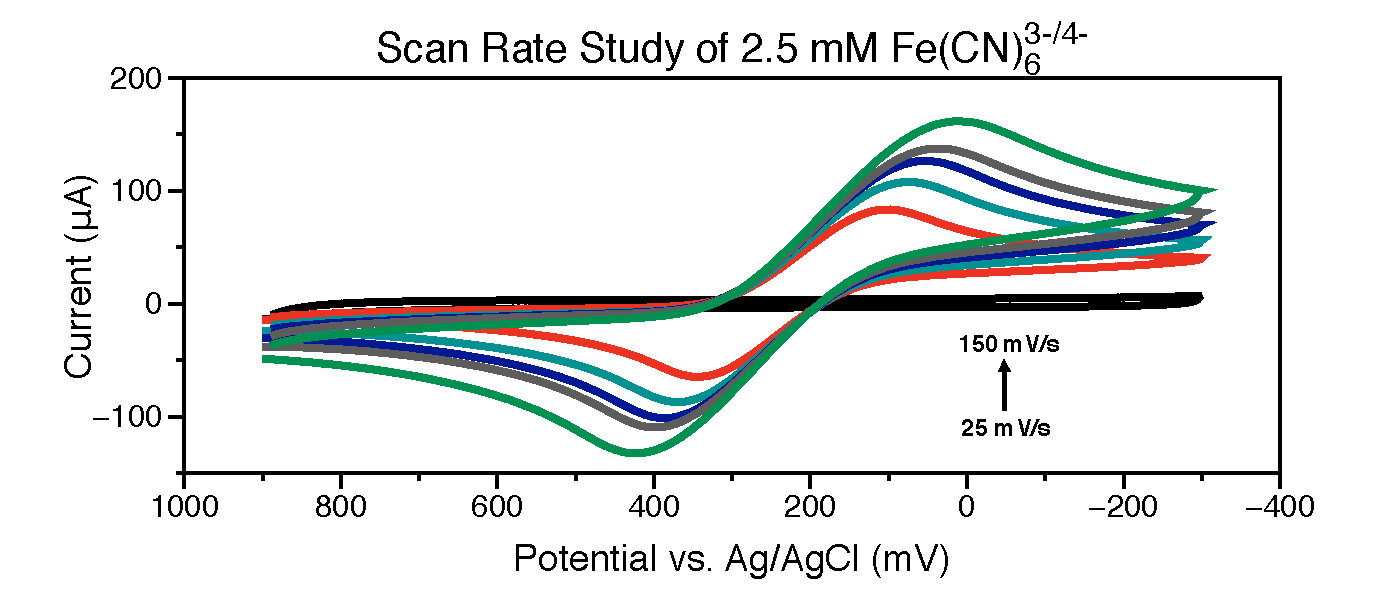

• Microfabricated 3-in-1 electrodes and micro electrode arrays

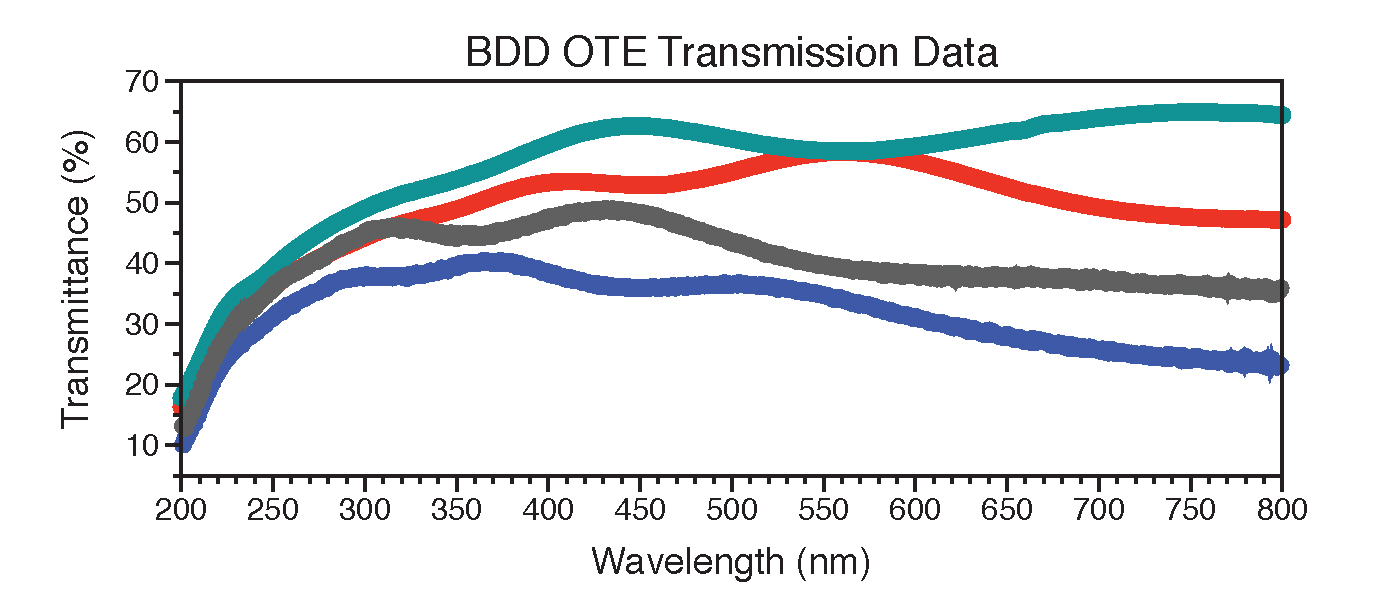

• Optical transparent electrodes

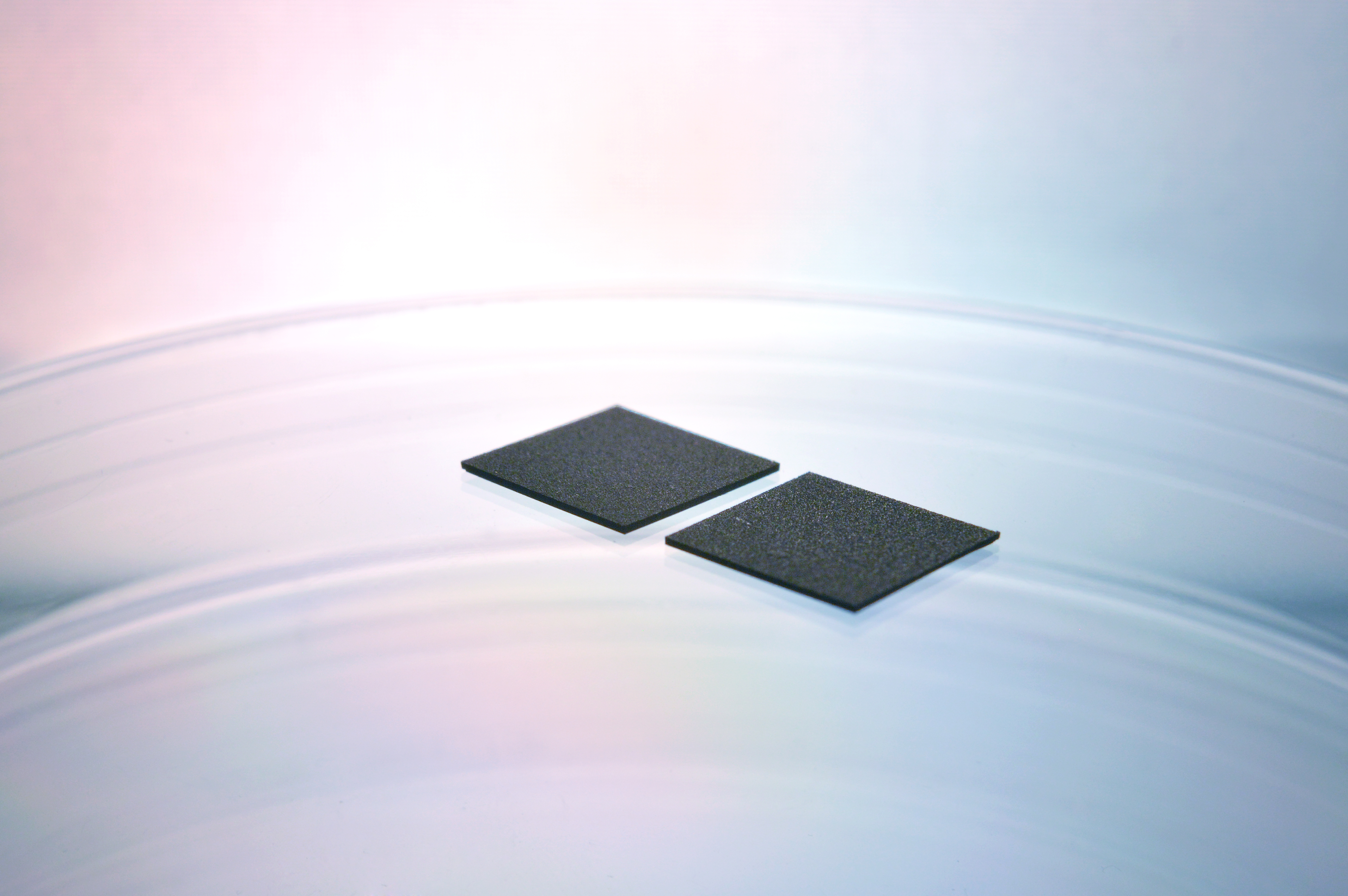

• Free standing and semi free standing BDD foils

• Flexible Parylene-C housed electrodes and

• Micro fibers

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW