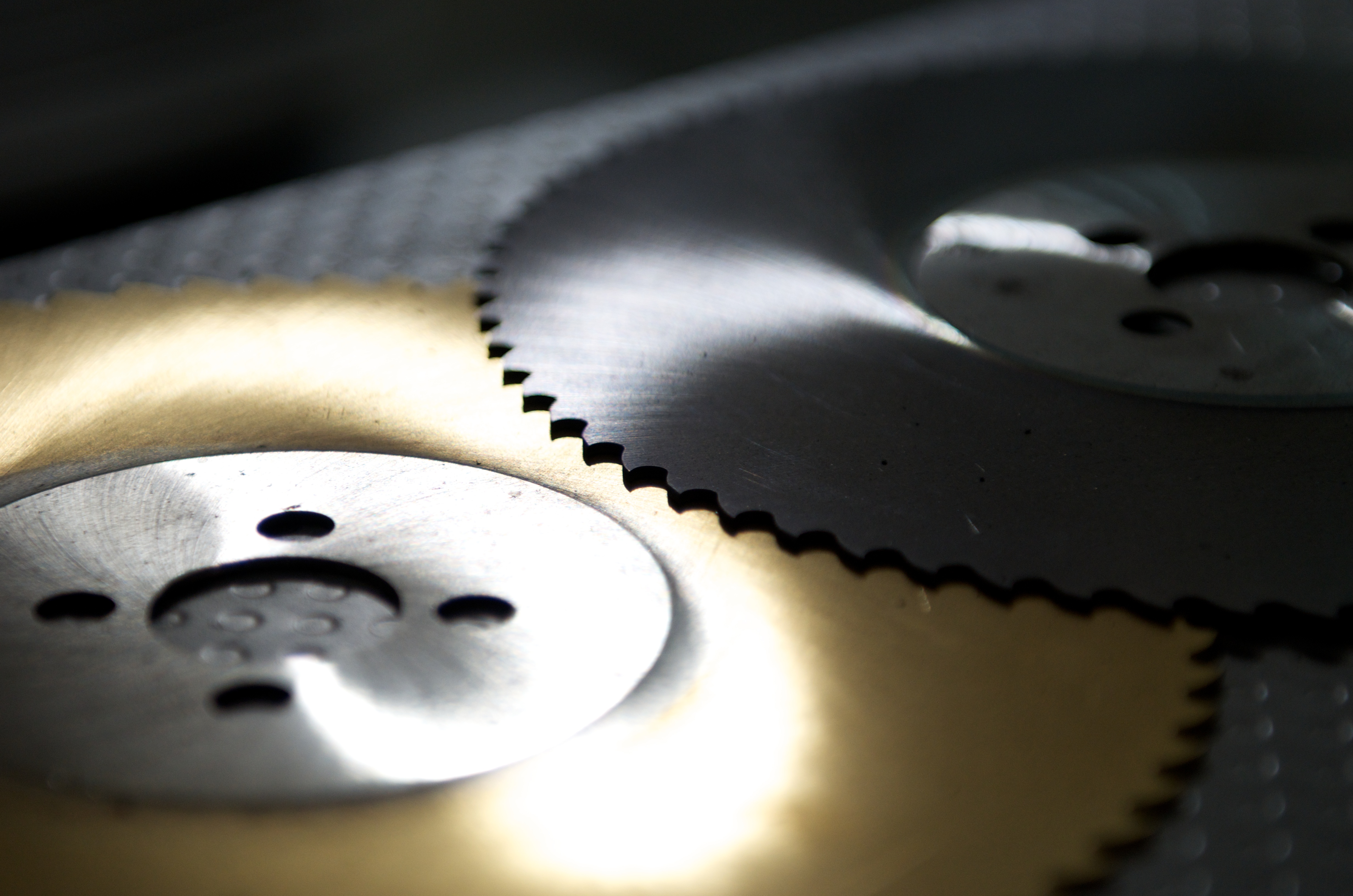

As production demands are greater than ever, manufacturers and users of industrial tools and parts are under constant pressure to increase their productivity. High performance coatings have become increasingly important in manufacturing to achieve this goal. Fraunhofer leads the field of thin film coating technologies (physical vapor deposition, PVD) and offer the development of high performance wear coatings and the associated coating services. Our customers include end users as well as manufacturers of cutting tools and wear components.

Coating Development

Coating & Process Development Solutions

Fraunhofer USA CMW dedicates all resources and expertise of our operations to meet and exceed the needs of our customers. With our extensive experience in industrial, applied research and our state of the art equipment, we are able to provide first rate technology solutions for your coating and process development needs in areas such as machining and wear problems. We also offer coating characterization and consulting services. Typical technology solutions include:

- PVD coating development for machining and wear issues

- In-house performance and machining tests

- Coating characterization

- Consulting services to support your coating, cleaning and characterization needs

We provide all standard plus custom designed coatings. Tailoring coatings to customer specific requirements is one of our key strengths. Our facility is equipped with fully automated PVD systems using the latest plasma sources.

Premium Quality

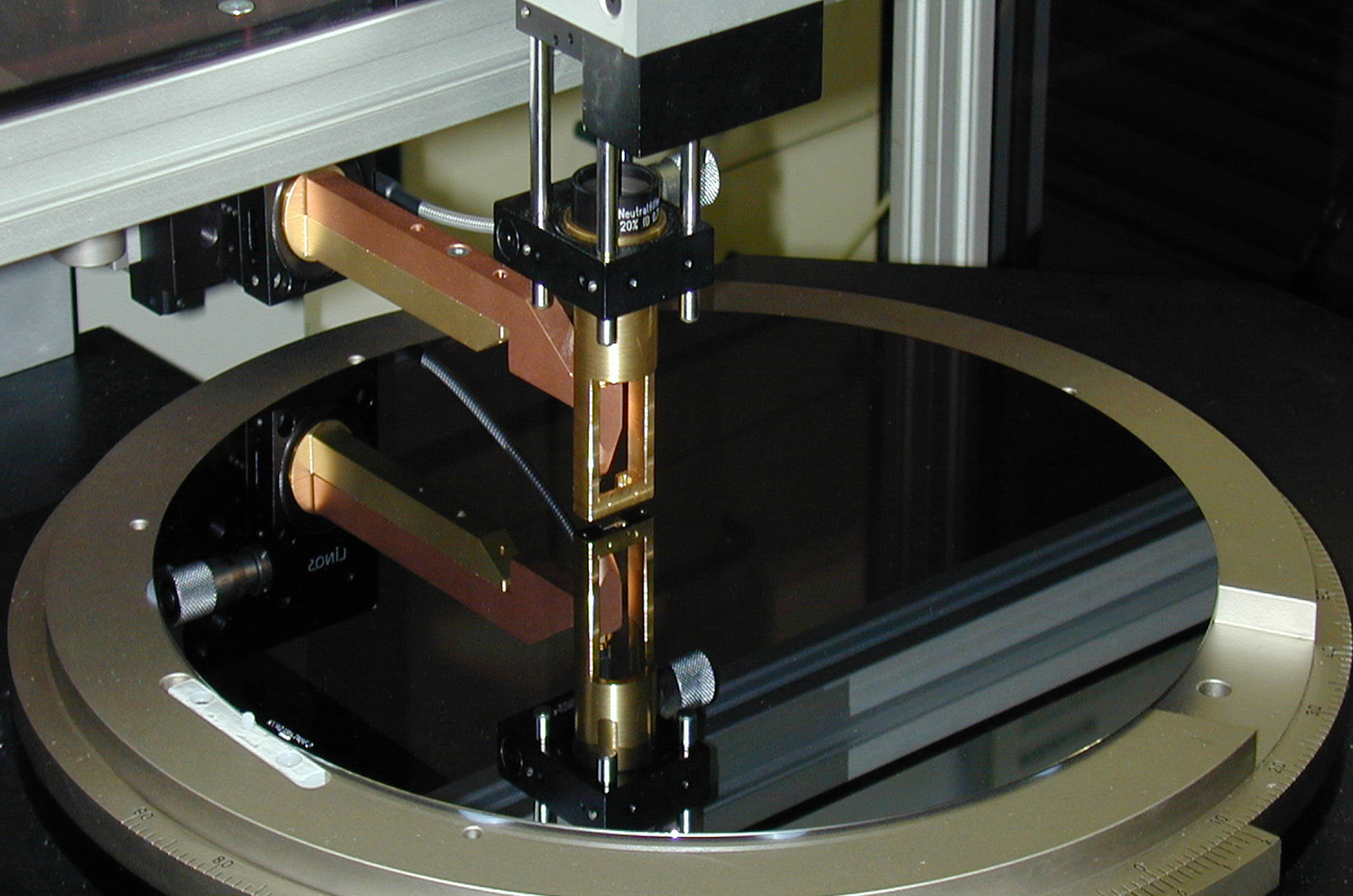

Customers turn to us because we provide them with high quality coatings, fast turnaround times, careful handling of their products and thorough inspection throughout the coating process. We are able to dedicate machines for orders to avoid cross contamination. In addition to visual inspections, we also use Fraunhofer's LAwave quality control machine, an innovative non-destructive testing system, as part of our inspection process.

As specialists for smaller coating batches, we deliver:

Premium quality service tailored to your specific requirements

High degree of flexibility

Fast turn-around time

Thorough inspection

Dedicated machines and team

Assurance of no cross contamination

Fraunhofer USA Center Midwest CMW has been ISO 9001 certified since 2003

Offered Coatings

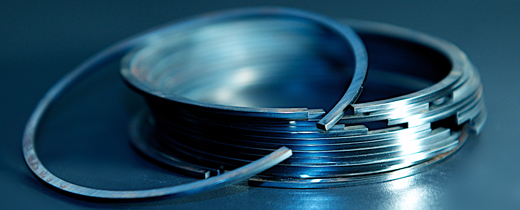

Coatings offered include standard coatings: AlTiN, TiAlN, TiN, ZrN, AlCrN

Other possibilities include:

Metal nitrides, metal alloy nitrides, metal carbides, metal carbonitrides and borides

Fraunhofer's Diamor® (ta-C) and other DLC coatings.

Nanostructure and nanolayer coatings for highly stressed surfaces on forming and forging tools.

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW