Overview

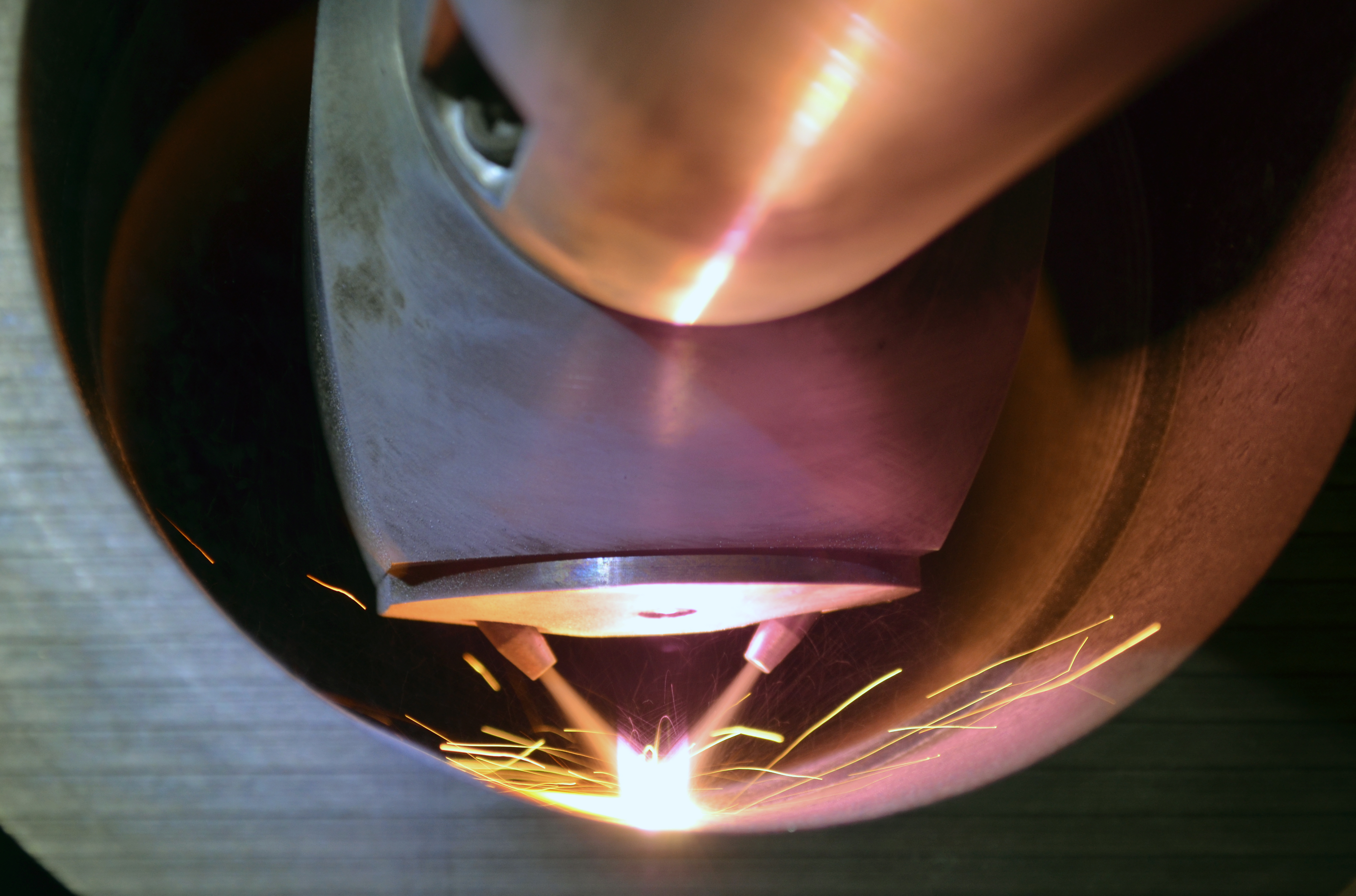

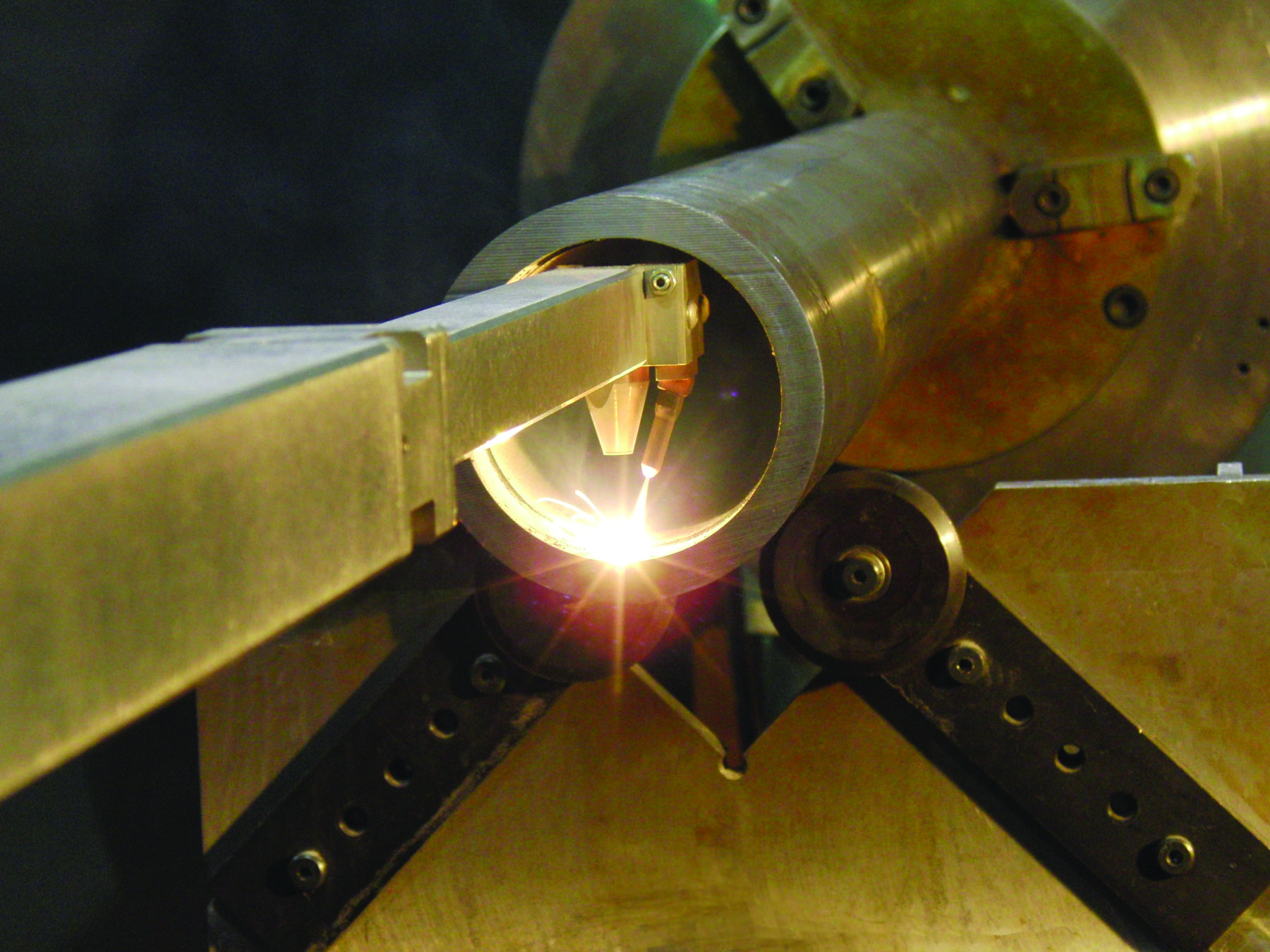

Fraunhofer has pioneered the development of state of the art innovative processing heads which enable laser cladding to be carried out inside tubes, pipes and other hard to reach places. Our ID head features our latest innovative design concepts and features internal water cooling and powder delivery which allows the head to operate reliably in hostile environments whilst traveling up to 39 inches (1000 mm) deep inside tubes which are smaller than 4 inch (100mm) internal diameter. Our quick change cover slide design allows for rapid change out of the consumable protective lens minimizing machine down time.

| Minimum tube diameter | Maximum clad length | Maximum laser power | Compatible lasers |

| 4" (~ 100 mm) | 39.4" (1000 mm) | 3 kW | Fiber, Disk and Nd. YAG lasers |

Advantages

- Ability to reach inside tubes and hard to access areas

- Robust and reliable performance

- Internal supply of all process media (cooling water / powder / shield gas)

- Optic performance monitoring system to ensure consistent coating quality

- Accepts wide variety of materials

Fraunhofer USA Center Midwest CMW

Fraunhofer USA Center Midwest CMW